Our services

Paldiski Tsingipada AS is one of the largest providers of hot dip galvanizing and Duplex (zinc + paint) services in Scandinavia and the Baltics.

10+ years of experience

10000 t protected metal

500+ satisfied customers

Quality

We are continuously improving our management system and streamlining our processes to comply with requirements. We prefer stable partnerships with reliable suppliers.

Environment

Environmentally sustainable production, where we follow all environmental aspects, legislation, requirements and laws related to production and act in the most environmentally friendly way possible.

Customer focus

Customers come first! We help our customers meet their needs and wishes by offering an ever-increasing range of complementary coating services.

Hot-dip galvanizing

Hot-dip galvanizing gives the steel parts a layer of zinc to protect them from corrosion. The thickness of the zinc layer is quite thin at 70 – 100 µm (micrometres), but it is the most effective way to protect steel from corrosion. Galvanized parts do not require maintenance in a normal environment for ~50 years. The zinc layer also has the ability to ‘repair’ itself, i.e. up to 5mm of damage and scratches, zinc can be kept corrosion resistant by an electrochemical process.

Hot dip galvanizing options

- Max. dimensions of the item to be covered: 6,8 x 1,35 x 2,55 m

- Max weight of galvanized part: 5,3t

- Post-treatment: passivation or staining

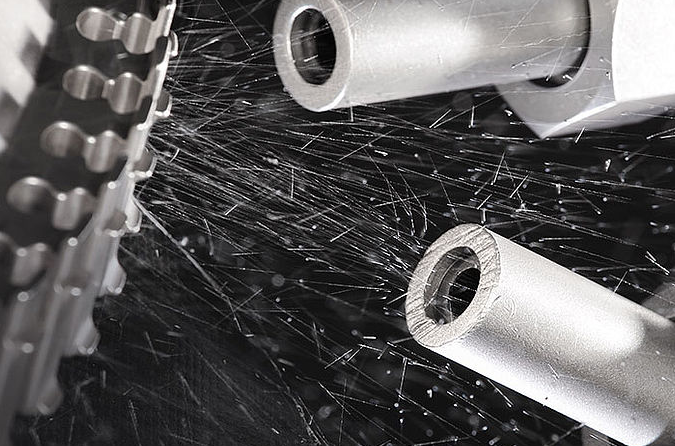

Hot-dip galvanizing in a spinning line

Hot-dip galvanizing is used for high-quality hot-dip galvanizing of small parts and also threaded parts. The line operates on the centrifugal principle and the zinc coating is carried out at a temperature ~100° higher than conventional zinc coating. This ensures high quality hot-dip galvanizing of small parts, especially threaded parts, in accordance with ISO 10684.

Hot-dip galvanizing by the drum method:

- Max length of detail to be covered: 500 mm

- Max weight of galvanized part: 6 kg

Duplex: zinc + colour

The DUPLEX coating system consists of hot dip galvanizing and powder coating. The powder coating oven, which measures 7m x 1.4m x 2.4m, is installed as an extension of the galvanizing line and allows us to quickly powder coat hot-dip galvanized parts immediately, thus ensuring the best possible colour pick-up. We have RAL and RR colours in our colour range. As a standard, we coat the surfaces of the parts to be painted with a powder coating of 70+/-5 microns, in other cases it is a special arrangement.

Other services

- Passivation – this process results in the galvanised part getting a thin additional layer of zinc, which in turn protects the zinc from oxidation (so-called white rust) and the parts retain their beautiful commercial appearance over a long period of time.

- Shotblasting – we carry out blasting on an automatic line and also manually for larger parts. Shotblasting helps to build up the zinc layer and removes sharp edges from the workpiece.

- Coating Thickness Measurement – We measure the thickness of the coating according to the customer’s specification and issue a measuring report.